When sourcing furniture for hotels, apartments, or commercial spaces, you’ll often hear two terms: OEM and ODM. They sound technical, but the idea behind them is actually quite simple. Understanding the difference can help you choose the right manufacturing model, control costs, and bring your furniture concept to life more efficiently.

This guide breaks it down in plain language—no factory jargon required.

What Is OEM Furniture Manufacturing?

OEM stands for Original Equipment Manufacturer. In an OEM model, you provide the design, and the manufacturer produces the furniture according to your exact specifications.

Think of it as: your idea + their manufacturing capability.

Key Features of OEM Furniture

- You own the design and brand

- The manufacturer follows your drawings, materials, and standards

- High level of customization

- Ideal for unique hotel or apartment projects

When OEM Makes Sense

- You already have detailed designs from an architect or designer

- You want full control over style, dimensions, and finishes

- Brand differentiation is a priority

OEM is commonly used in mid-to-high-end hotel projects, branded residences, and bespoke apartment developments.

What Is ODM Furniture Manufacturing?

ODM means Original Design Manufacturer. In this model, the manufacturer already has proven designs, structures, or product concepts. You can select and adapt them to your needs.

In simple terms: their design + your customization + your brand.

Key Features of ODM Furniture

- Faster development time

- Lower design and tooling costs

- Tested designs with stable structures

- Flexible customization (size, color, finish, fabric)

When ODM Is the Better Choice

- Project timelines are tight

- You want cost efficiency without sacrificing quality

- You need reliable, market-proven furniture solutions

ODM is especially popular for standard hotel rooms, serviced apartments, and large-scale developments.

OEM vs ODM: What’s the Difference?

| Aspect | OEM | ODM |

| Design ownership | Client | Manufacturer |

| Customization level | Very high | Medium to high |

| Development time | Longer | Shorter |

| Cost structure | Higher upfront | More cost-effective |

| Best for | Unique, branded projects | Standardized or fast-track projects |

Can You Combine OEM and ODM?

Absolutely—and many successful projects do.

For example:

- Use ODM for beds, wardrobes, and desks with minor customization

- Use OEM for statement pieces like lobby furniture or signature headboards

This hybrid approach balances design impact, cost control, and delivery speed.

Choosing the Right Manufacturing Partner

Whether you choose OEM, ODM, or a mix of both, your manufacturer should offer:

- Strong engineering and production capability

- Experience with hotel and apartment projects

- Clear communication and project management

- Reliable quality control and delivery timelines

A good partner doesn’t just make furniture—they help you avoid mistakes before production even starts.

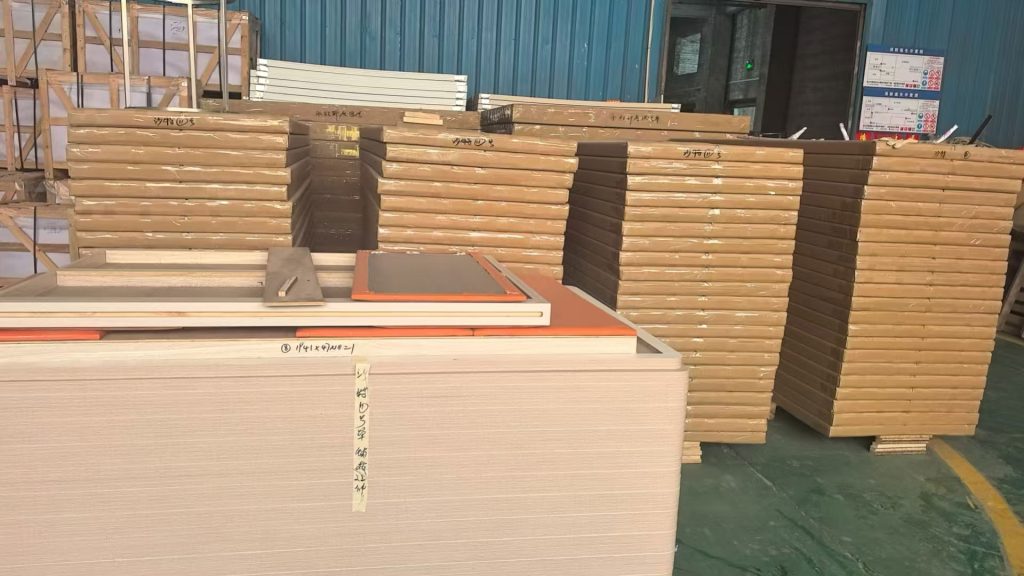

Working with Assomsen Furniture

Founded in 2004, Assomsen Furniture is a professional manufacturer of bespoke furniture for hotels and apartments. With over 22 years of industry experience, we support developers, hotel owners, and designers through both OEM and ODM manufacturing models.

From fully customized designs to optimized, ready-to-adapt solutions, our team focuses on delivering reliable, cost-effective furniture that meets real project needs—on time and to specification.

If you’re planning a new hotel or apartment project and want to explore the right OEM or ODM approach, feel free to contact us at assomsenhotelfurniture@gmail.com. We’re always happy to help you find the most practical solution for your space.